Lame Circolari

Focalizzati nella costante ricerca e sviluppo di nuovi acciai che possano migliorare le caratteristiche di durata e resistenza nelle diverse applicazzioni,le nostre lame vengono prodotte con gradi diversi di precisione e finitura per poter garantire il massimo delle performance sulla tipologia di materiale da tagliare.

Trattamenti termici sottovuoto di alta qualita’ esaltano le performance e la durata delle lame.

I parametri piu’ importanti per una lama sono:

- Massima resistenza del filo tagliente

- Adeguata tenacita’

- Massima resistenza alle scheggiature

- Tolleranze ristrette sul spessore, planarita’ e parallellismo

Emmebi puo’ produrre lame fino a 600mm di diametro esterno con finitura rettificata e fino a 420mm di diametro esterno con finitura Lappata.

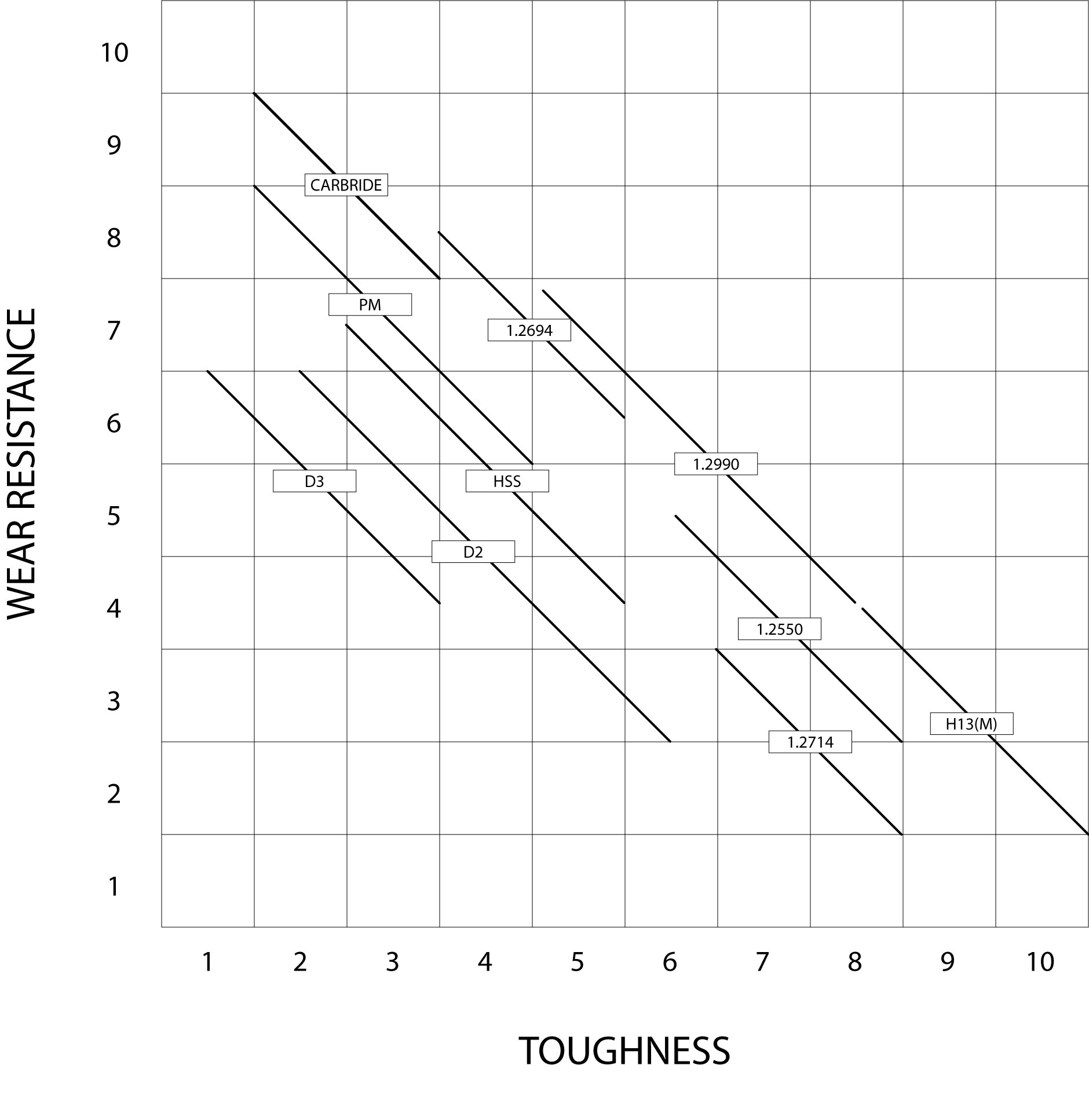

Toughness Wear Resistance Graph

Commody used Knife grades for different applications:

| Tool Materials | Applications |

| AISI-D3/1.2080 | Thin gauge of ferrous and non-ferrous materials |

| AISI-D2/1.2379 | Medium gauge mild steel and thin gauge stainless steel,silicon steel, heat treated steel and thick gauges of non ferrous |

|

AISI-H13(M)/1.2345 &AISI-H13/1.2344 |

Heavy gauges of stainless steel and mild steel, structural steel with high hardness where toughness is important |

| DIN 1.2990 | Structural steel, constructional steel (with high manganese and carbon content). High Strength Material upto 1600MPa, Heat Treatable steel |

| DIN 1.2714 | Medium and heavy gauge slitting but medium degree of toughness is required |

| DIN 1.2694/HPS | Extra thin gauges of the very hard material like hardened stainless steel |

| AISI-MS/1.3343 (H.S.S.) | Thin and extra thin gauges: for narrow and tight slitting with high quality of slit edge |

| PM Grades ASP23, 30 | Better life (2x-3x) compared to Conventional HSS |

| Carbide | CRGO, thin gauges of high tensile materials, very high tonnage between 2 regrinds |

Achievable manufacturing tolerances on Knives & Metal Spacers:

| OD | Precision Grade | Extra Precision Grade | |||||

| Thickness | Fatness (Within) | Thickness | Flatness (Within) | ||||

| (in mm) | Tolerance | T≤2 | 2<T≤5 | T>5 | Tolerance | 2<T≤5 | T>5 |

| Upto 255 | ±0.003 | 0.1 | 0.040 | 0.010 | ±0.001 | 0.020 | 0.00 |

| 255≤D≤365 | ±0.004 | 0.1 | 0.050 | 0.015 | ±0.001 | 0.030 | 0.005 |

| 365≤D<435 | ±0.005 | 0.1 | 0.060 | 0.020 | ±0.003 | 0.040 | 0.006 |

| Above 435 | ±0.006 | 0.1 | 0.070 | 0.025 | ±0.004 | 0.050 | 0.010 |

General Bore Tolerance: G6, G7, H7, F7, F8

General OD Tolerance: 0/-0.02mm

*Any special tolerance for parallism, flatness and bore can be made as per customer requirement

**All the dimensions are in mm