Circular Blades

We focus on the constant research and development of new steels that can improve durability and strength in different applications, our blades are produced with different degrees of precision and finishing to ensure maximum performance on the type of material to be cut.

High quality vacuum heat treatments enhance the performance and durability of the blades.

The most important parameters for a blade are:

Maximum cutting edge resistance

Satisfactory tenacity

Maximum splinter resistance

Limited tolerances on thickness, flatness and parallelism

Emmebi can produce blades up to 600 mm in external diameter with surface finish and up to 420 mm in diameter with lapped finish.

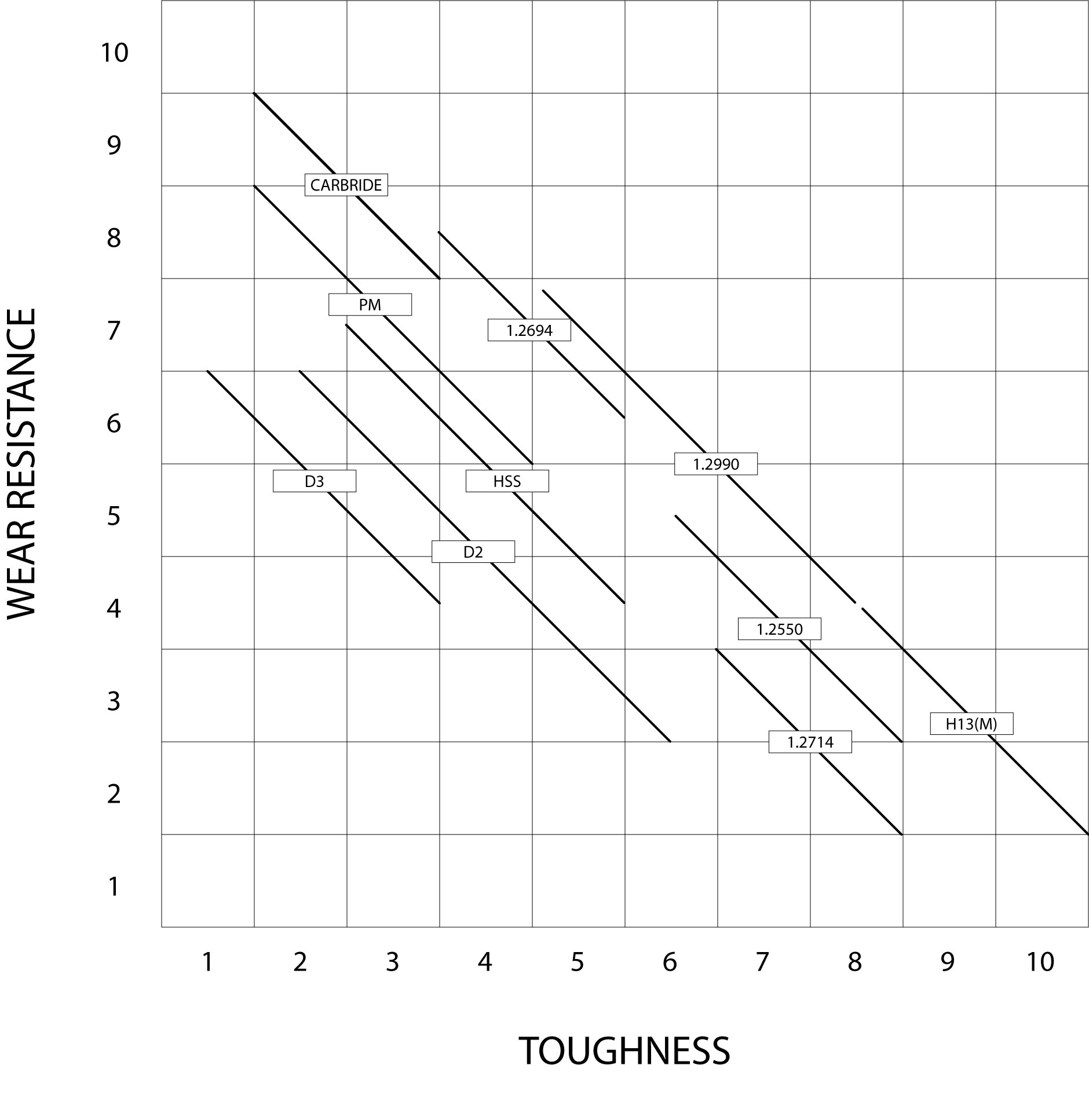

Toughness Wear Resistance Graph

Commody used Knife grades for different applications:

| Tool Materials | Applications |

| AISI-D3/1.2080 | Thin gauge of ferrous and non-ferrous materials |

| AISI-D2/1.2379 | Medium gauge mild steel and thin gauge stainless steel,silicon steel, heat treated steel and thick gauges of non ferrous |

|

AISI-H13(M)/1.2345 &AISI-H13/1.2344 |

Heavy gauges of stainless steel and mild steel, structural steel with high hardness where toughness is important |

| DIN 1.2990 | Structural steel, constructional steel (with high manganese and carbon content). High Strength Material upto 1600MPa, Heat Treatable steel |

| DIN 1.2714 | Medium and heavy gauge slitting but medium degree of toughness is required |

| DIN 1.2694/HPS | Extra thin gauges of the very hard material like hardened stainless steel |

| AISI-MS/1.3343 (H.S.S.) | Thin and extra thin gauges: for narrow and tight slitting with high quality of slit edge |

| PM Grades ASP23, 30 | Better life (2x-3x) compared to Conventional HSS |

| Carbide | CRGO, thin gauges of high tensile materials, very high tonnage between 2 regrinds |

Achievable manufacturing tolerances on Knives & Metal Spacers:

| OD | Precision Grade | Extra Precision Grade | |||||

| Thickness | Fatness (Within) | Thickness | Flatness (Within) | ||||

| (in mm) | Tolerance | T≤2 | 2<T≤5 | T>5 | Tolerance | 2<T≤5 | T>5 |

| Upto 255 | ±0.003 | 0.1 | 0.040 | 0.010 | ±0.001 | 0.020 | 0.00 |

| 255≤D≤365 | ±0.004 | 0.1 | 0.050 | 0.015 | ±0.001 | 0.030 | 0.005 |

| 365≤D<435 | ±0.005 | 0.1 | 0.060 | 0.020 | ±0.003 | 0.040 | 0.006 |

| Above 435 | ±0.006 | 0.1 | 0.070 | 0.025 | ±0.004 | 0.050 | 0.010 |

General Bore Tolerance: G6, G7, H7, F7, F8

General OD Tolerance: 0/-0.02mm

*Any special tolerance for parallism, flatness and bore can be made as per customer requirement

**All the dimensions are in mm